Note to self: if a print pops loose… just slap on a brim and try a different orientation. Easy fix, lesson learned. ✅

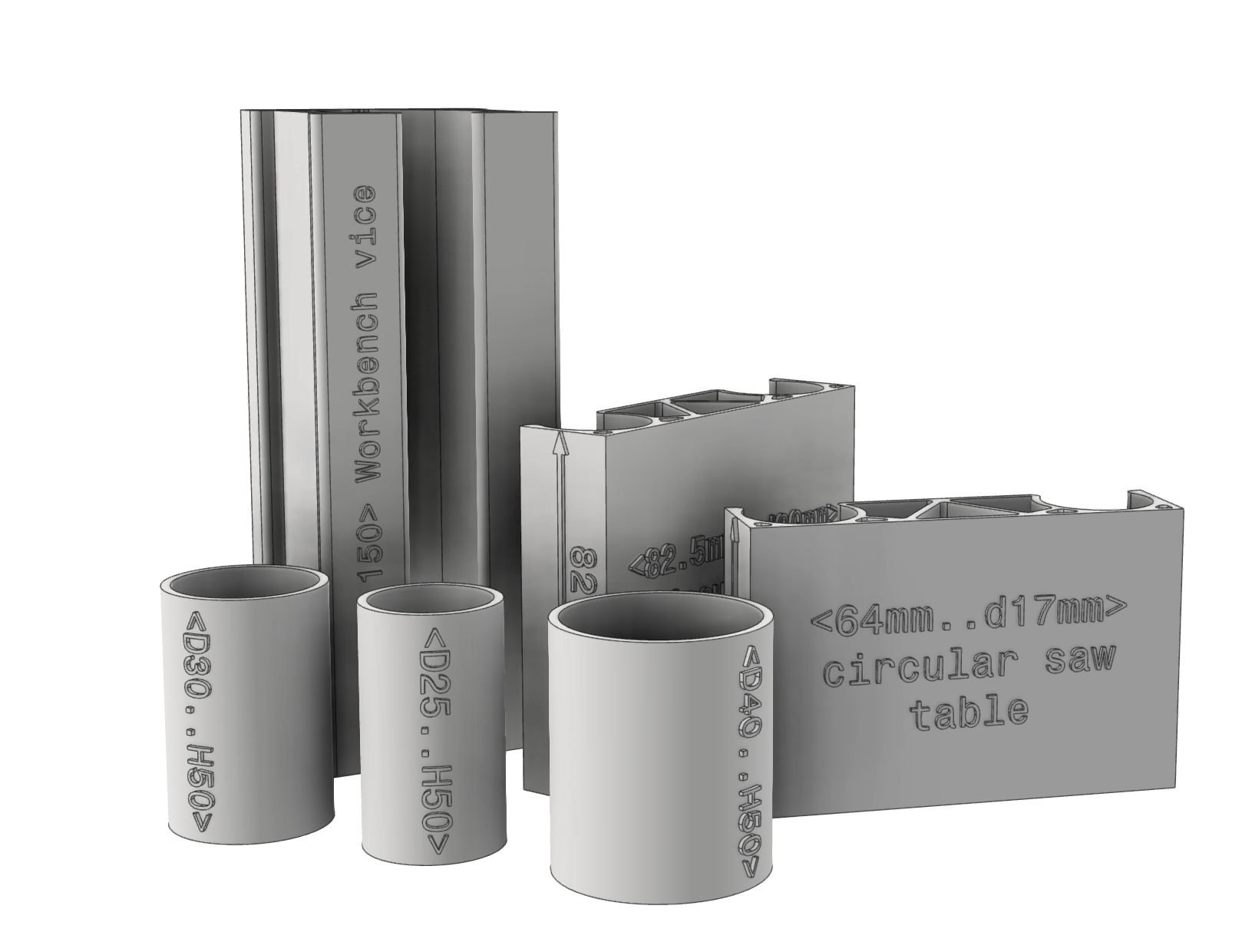

Next, I cooked up a set of rigs for the very first lug. These are my secret weapons for filing the bamboo tubes down to the perfect diameter. The big rig clamps right into the vise (yep, totally over-engineered… but that’s how I roll 💪). The smaller ones slide over the tube with a 1 mm tolerance so I can mark the exact circle I need to file. And the hole at the bottom? That’s the final boss. If the tube slips through, I know I’ve shaved off just enough material.

The first few tubes I’ll shape by hand—classic craftsmanship. Later on, I’ll probably switch to the wood lathe. Faster, smoother, and honestly just way more fun.

Meanwhile, the printers are happily churning out new parts, and I’m giving the earlier printed lug a nice finishing coat. Not urgent, but the perfect “between other tasks” project.

Oh, and I ordered a complete bike as a donor. Turns out it’s cheaper than buying all the parts individually! Delivery’s due next week—hopefully just in time to start assembling the frame. Realistically, it might take a bit longer, but hey, that’s progress. Still missing one crucial piece though: a proper BSA68 bottom bracket insert. That’ll be the key to fitting the crankset once everything’s glued up.

This afternoon I also did some tinkering in the workshop. At first, I figured I’d just use a file to adjust tube diameters, but then it hit me: we’ve got a circular saw with horizontal sliders. Block those at the right distance and boom—you’ve basically got a reverse lathe. Took some measurements, and voilà: more rigs were born. 🔧

Reflection

Not every workflow needs fancy gear. Sometimes, a plain old saw table gets the job done just fine.