Today I made a huge step forward in printing carbon-reinforced polyamide (PA12CF). Contrary to what you often read online, it turns out that a little extra cooling is actually recommended. Not a major adjustment in the print settings, but the effect is impressive: print quality has visibly improved. An unexpected win.

Why PA12CF?

Carbon-reinforced polyamide, often called PA12CF, is a high-performance 3D printing material. It combines the toughness and heat resistance of nylon (PA12) with the stiffness of chopped carbon fibers. The result is:

- Strong and lightweight parts — ideal for structural components.

- Low warping compared to unfilled nylon.

- High temperature resistance — parts can handle demanding conditions.

- Dimensional stability — prints stay accurate even under load. For this project, that balance is critical: I need parts that are strong enough to handle real stress on a bicycle, but also precise and repeatable in production.

Small Tweak, Big Difference

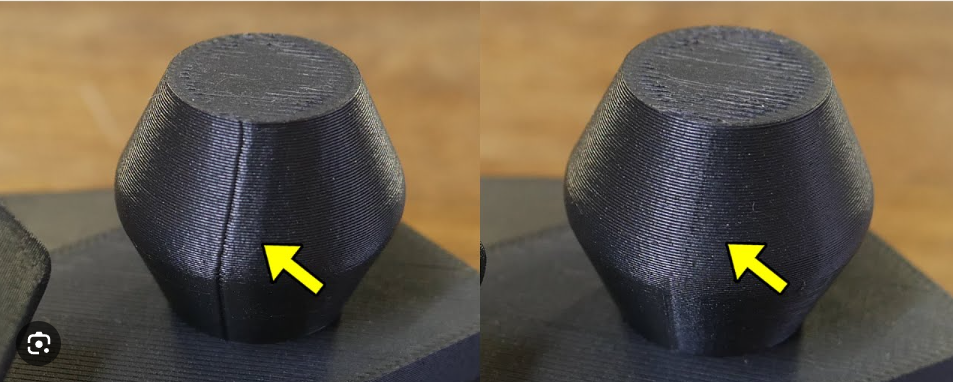

The trick lies in nuance. Too much cooling makes PA12CF brittle or causes delamination. But a slight airflow helps to sharpen details and build up layers more consistently. For the first time today, that tweak made a visible difference.

Further Fine-Tuning: Scarf Seams

With that base in place, I could focus on Scarf Seams. Seams are the little scars or lines where each new layer starts or ends. Normally, you get a straight vertical line running along the model. Scarf Seams tackles this smartly: instead of stacking the seam in one spot, it distributes it diagonally over several layers. The result:

- No hard, continuous line.

- A smoother surface where the seam blends in.

- Much better aesthetics, especially on visible functional parts.

Closing the Day

I ended the day by reprinting an earlier version of the Seat Lug. This time everything should be correct. If it works out, tomorrow I can finally shift my focus back to design rather than troubleshooting print quality.

Reflection

“A small tweak can make a big difference.” Today felt like another step toward a production-ready setup. First the surprising boost from cooling, then the finesse of Scarf Seams. It’s the details that lift the whole process to the next level.